As you may have read from my previous posts, a historical rebuild / refurb of this car has introduced some electrical gremlins.

Whilst investigating why the battery totally discharged every few days I noticed that there was considerable spurious wiring hanging out of the dash for a) a radio which wasn’t fitted b) a rocker switch fixed to the centre console for something or other – unknown. There was also missing bulbs in the dash and issues with non functioning interior lighting, not to mention a random indicator that seems to make it’s own mind up whether it works or not.

So whilst I was waiting for some paint to dry I decided to investigate and remove the spurious wiring.

Got a little carried away.

Now it’s all in bits I will put it back together with a little more care than the last time, check and test all of the wiring and replace with LED in the dash and interior – might even do the the indicators as well.

The more I look into the electricals the more I need to get down into the detail in order to figure it out. I am now doubting whether the basic wiring loom has been re-installed properly as there are so may wires that have simply been cut rather than the problem investigated and fixed

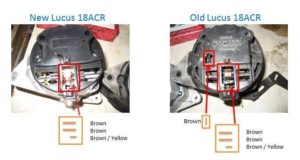

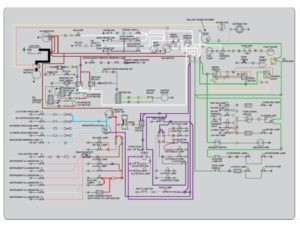

After some research on line and of course the expert knowledge of the Stag Owners Club I have come up with the following sources of information that should help me.

These are the starting points. As I work my way around the car and notice anomalies or modify/add new elements, I will make changes to these pictures and post on the Wiring and Electrical Diagrams page (here).

Wiring Diagram

One strange phenomenon was the left hand indicator. It has always been, lets say weak, in that it sometimes worked and sometimes not. But recently the problem has worstened to the point where engaging the left hand indicator flashes the reversing lights. Looking at the circuit diagram above this seems impossible and I feared a new loom was called for. But, after talking to some helpful SOC members I eventually diagnosed the problem as the indicator earthing through the reversing lamps. Turns out that the earth for the indicator ignored a layer of paint between it and the chassis. Probably not there when the car was disassembled before it’s respray, but definitely present afterwards and not removed to provide a good clean earth.