Today I braved the low temperatures for another few hours of disassembly. The throttle cable and the throttle peddle were first out followed by the footwell backing boards and insulation behind them. Then the speedo cable and RPM cable followed by the heater control cable. As I am dismantling I am taking copious photos and trying to label everything in ziplock bags and then taking of photos of the bags so I know where everything went.

Next was the wiper motor, wiper cable and the trunking that protects it. All was going well until I tried to remove the wiper boxes. I was curious as to why the wiper arm mounting and lock nut had been painted body colour as the lock nut was originally chromed. The reason was that the lock nuts on both sides had ceased onto the wheel box threads and been left in-situ when the tub was repainted, rather than being removed. Both will need replacing along with the rubber gromets they sit on. Rimmers has them listed as Wiper Box – 32 Teeth – 122781 Qty Req-2, vehicles from 1969. I will need to check if mine is the 32 teeth variety by looking at the gear wheel in the wiper motor which should have 160 stamped on it.

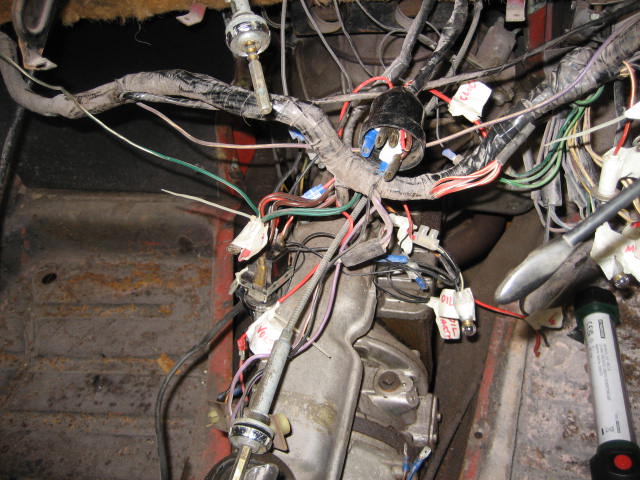

At this point I needed to warm up, but there isn’t much more to do before the front tub can be removed. Just the brake and clutch master cylinders, the heater and disconnection of some more of the wiring loom.