|

|

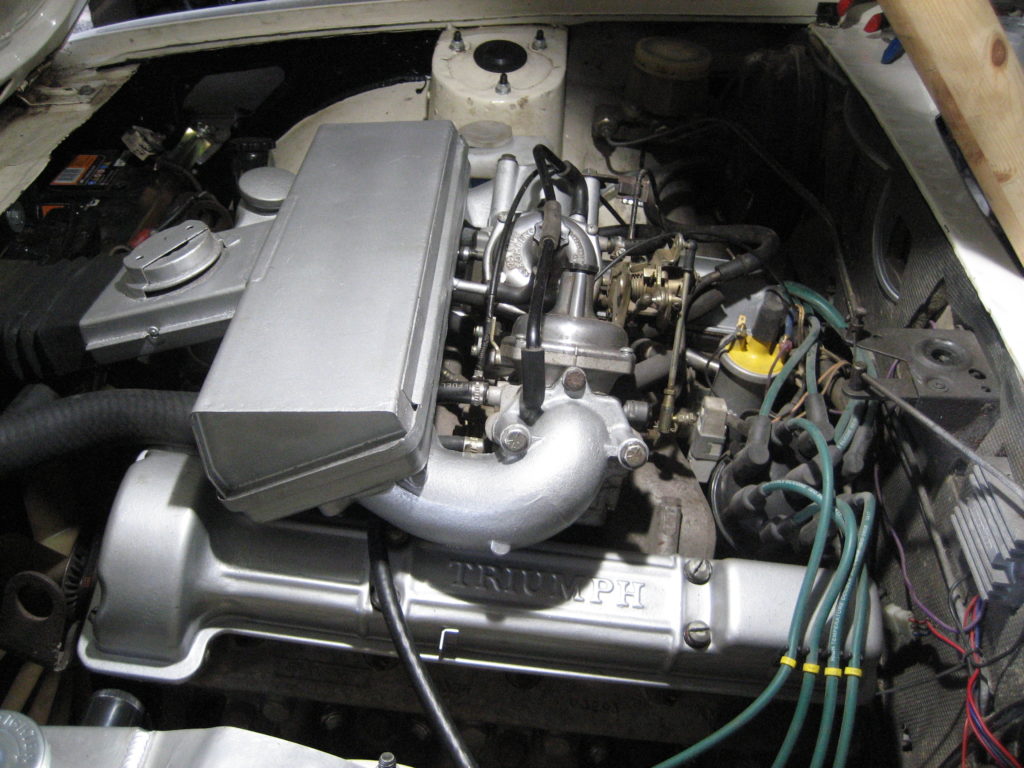

With the cooling system now upgraded and all the fluids back in place and topped up, I ran the engine to temp to check everything was working. 3 problems:

- The top hose poped off once the engine was warm;

- There was a fuel leak at the joint of the steel fuel pipe and the rubber hose at the rear;

- There was a puddle of fresh oil.

The first 2 were easy fixes – done in a few minutes. I did some research on the third.

There are some usual suspects when it comes to oil leaks on a Stag. The cam covers can leak through the cork gasket, the half-moon rubbers or the cam cover screws. Underneath the oil pump has two internal seals that can leak along with a 3rd between the pump and the block. Then there is the oil transfer housing that also has 2 seals that perish and/or harden over time and cause leaks. The final source of dripping oil after a run, is the rear crankshaft oil seal.

The rear crankshaft oil seal is the most onerous to change as it requires the gearbox to come out first. Not something to contemplate until all the others have been sorted first.

I started with the cam covers. They came off easily although thet need some cleaning internally as the gaskets had been held in place with silicon sealant. Having removed all of the sealant I decided to give them a new coat of paint along with the air intake elbows.

As these were drying I tackled the oil pump and oil transfer housing. Neither can be done from above – you have to get underneath and also remove the right hand exhaust at the manifold. You need to remove the oil filter first and then you can remove the oil pump and the transfer housing.

Replacing the seals is straight forward once the pump and transfer housing were cleaned. I did have a little trouble trying to figure outwhich new seal was which as they came all in one back together. In the end I stripped the pump and housing and laid out all of the old seals next to the new.

While I was had the pump in bits I also replaced the drive shaft. The old one had very little wear but I didn’t know that until it was stripped. As they are so cheap, I bought a new one just in case, and replaced it anyway.

The trickiest part of this particular job was replacing the transfer housing on the block. My stag is an auto with the BW35 box. The clearence between the Bw35 breather pipe and the oil sensor which is screwed into the top of the oil transfer housing is very tight. After half an hour of profanities, I managed to get it installed by

- Sticking the sealing ring into the recess in the housing using a little flexible gasket sealant – as it kept dropping out of position;

- Starting the thread of the oil sensor into the housing before refitting the housing – I couldn’t start the thread with the transfer housing in place, there just wasn’t room;

- Disconnecting the sensor wire and re-connecting only after everything was tight.

I’ll re-asseble the cam covers tomorrow and turn the engine over to see if i’ve cured it.

Cam covers back on, but I haven’t turned her over. The reason – I used a very thin smear of gasket sealant between the head and the cork gaskets. Mainly because the half moon seals stood a little proud of the block, and I wanted something to fill a potential gap if they didn’t compress when I tightened the cam covers up.

I will leave it all to settle and seal and start it next weekend.

Update – 26th April 2020

After the remedial work last week, I turned the key again. The re-connection of the radiator hose to the pump, had re-positioned the lower segment of the pipe so it interferred with the alternator again. This time I drained the coolant, removed the lower rubber segment and shortened it by a centimeter. When refitted this moved the pipe assembly out of the way of the alternator fan.

I ran it up to temperature once more – all well and NO OIL PUDDLE – success!!.