My exhaust has never been the quietest, but recently it has developed a very loud rasping rattle at revs above 3000. Rather than the sound of a purring engine as you pull away, you have the sound of a rattling tin can – not good.

I went up to GBS last weekend and saw Richard@GBS. He said that occasionay the inner sleive within these new single can exhausts, can move backward and rattle against the rear of the outer casing. He gave me a few stainless rivets and told me to place a rivet about 2cm from the seam and somewhere that can’t be seen. This should stop the inner sleeve moving.

Well as you can see above (photo taken from below), I have done this and the awful noise is still there.

Pre-Nurburgring Training

Although I have attended a couple of GBS Track Days recently I have never actually taken the car on the track. But this is going to change on 3rd June 2014 when I have registered for a track day at the Nurburgring with GBS and their German distributor.

Although I have attended a couple of GBS Track Days recently I have never actually taken the car on the track. But this is going to change on 3rd June 2014 when I have registered for a track day at the Nurburgring with GBS and their German distributor.

The day is a closed session (no public admittance) arranged by the German Pistenclub (pistenclub.de), so I have 8am until 16:30pm to do as many laps as I like along with 100 other cars.

As this is the first drive on a track for many years, I decided to get some professional help to brush up my technique and help me get a feel for my car at track speeds. If you were at Stoneleigh the other day you may have noticed a company called GEM Driver Training ( gemdrivertraining ). I noticed them in the magazine literature because they use an airfield close to me in Stafford.

Last Sunday I did their Track and Performance Driving Course. I can recommend it for anyone in my position. I wanted to understand some of the theory behind how a car handles on a track, and also brush up my track driving skills. Ewan Morris does an excellent job talking though car dynamics with the aid of some powerpoint.  He really understands what he is talking about as he has many driving teaching qualifications and many years of race experience. The session was not just theory either. We started in his Rover with some basic assessment and track orientation, but then I arranged for 1:1 tuition in my Zero for 45 minutes. Time to put the theory into practise. It was just what I needed. I now feel safer and more capable of enjoying a full day around the “Ring”. Thank you Ewan!!

He really understands what he is talking about as he has many driving teaching qualifications and many years of race experience. The session was not just theory either. We started in his Rover with some basic assessment and track orientation, but then I arranged for 1:1 tuition in my Zero for 45 minutes. Time to put the theory into practise. It was just what I needed. I now feel safer and more capable of enjoying a full day around the “Ring”. Thank you Ewan!!

Here’s his Facebook link GEM-Driver-Training

IACV Removal

As I have mentioned in several previous blogs, I have never been happy with the operation of the IACV. I believe the car only starts and idles because of two opposing problems: the first is that the IACV was wired back to front so even though it is turned off in the ECU it still remains circa 70% open when the ignition is on; the second is the diameter of the pipes leading into and out of it physically constrain the air flow. Together, these issues allow just sufficient air to the plenum to allow the car to start and idle (albeit very fast 1250 RPM warm idle). If I am right, then there is a third unseen problem. The airflow via the IACV is constant and un-metered, which means that the engine will be running lean. The proper answer is to install the IACV correctly along with a Lamda sensor and run closed loop, but I haven’t the time or inclination to do that at the moment since I have registered for the GBS Track Day at the Nurburgring in 2 weeks time. My priority is the get the car operating in the most reliable and predictable fashion ready for the trip to Germany. So I have decided to remove the IACV and revert the idle control to a simple throttle stop on the butterfly.

The proper answer is to install the IACV correctly along with a Lamda sensor and run closed loop, but I haven’t the time or inclination to do that at the moment since I have registered for the GBS Track Day at the Nurburgring in 2 weeks time. My priority is the get the car operating in the most reliable and predictable fashion ready for the trip to Germany. So I have decided to remove the IACV and revert the idle control to a simple throttle stop on the butterfly.

As you can see from the photo, it is quite a straight forward process to remove the threaded lug and replace with a standard bolt and a couple of nuts to lock it into position. The throttle can then be re-installed on the end of the plenum.

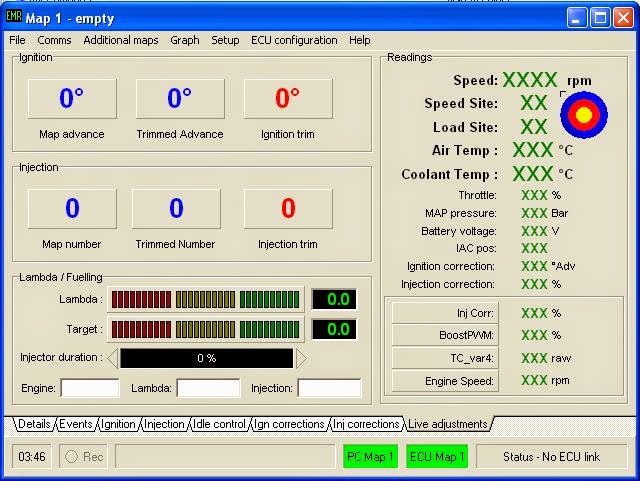

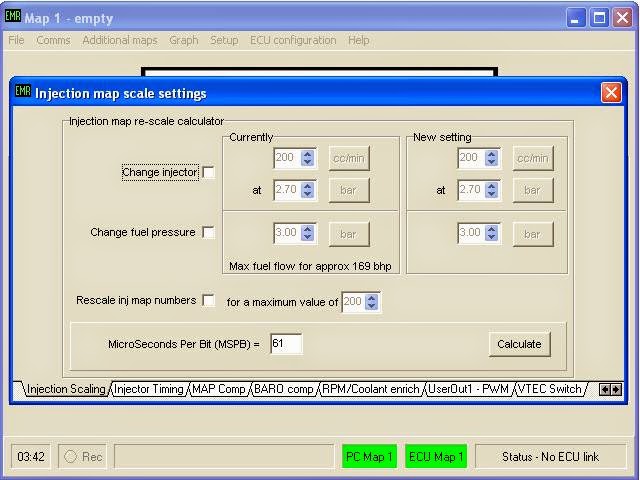

The real work in this job isn’t mechanical but it is in the trimming of the idle set-up in the ECU for warm idle and cold start. I found some instructions on the Emerald web site for trimming the warm idle:

If you disable the idle stabilisation function (as found in the “Idle control” page) and the overrun fuel cut off function (as found in the “Events” page) it will prevent these functions from hindering rather than helping while you initially get the engine fired up, throttles balanced and the idle set.

Assuming that the ECU is locking onto the crank sensor signal ok, then the main task is to get the engine fired up and up to temperature. This may (will probably) involve holding the throttle open slightly while you adjust the idle screw to hold the engine at a sensible rpm.

The next bit is a bit of a juggling act – you want to make sure that the fuelling is somewhere right, so just use the fuel trim keys (2 & 3) in the “Live adjustments” screen to add or take away fuel so the engine runs as smoothly as possible.

Once you’re happy that the engine is running smoothly, the engine rpm is ok for a hot idle speed and the throttles are fairly well balanced, you can shut the engine off and re-align the throttle position sensor via the PC software. Switch the ignition off/on (if you haven’t already) just to ensure that everything (e.g. fuel trims) are cleared, and re-start.

If you make changes to the MSPB number, keep the changes fairly small each time, (say steps of 4 or less) and remember to program the map to the ECU for the MSPB value change to take effect – you can do this with the engine running. The base map should get you most of the way there but the idle fuelling and very light throttle settings are most sensitive to injector/fuel pressure/engine differences so often require a little more attention and fine tuning.

Here is the link to the technical article on Cold Start Calibration.

Emerald_Cold_start_crib_sheet.pdf

Even though I am not an automotive engineer, following the process resulted in an engine that idles smoothly and starts without a problem from cold – albeit cold equating to 10 degrees at the moment. This may need some more work in the Winter.

Accelerator Pedal Stops

Another small job I have been meaning to do. The pedal position for the accelerator has never been where I expect it to be. Normally it should sit just below the height of the brake pedal so that your foot can move horizontally from brake to accelerator swiftly without having to lift your foot. It should then travel to 100% throttle open and have a physical stop to avoid stretching the accelerator cable. Having taken your foot off the pedal it should return to where it was just below the height of the brake.

Another small job I have been meaning to do. The pedal position for the accelerator has never been where I expect it to be. Normally it should sit just below the height of the brake pedal so that your foot can move horizontally from brake to accelerator swiftly without having to lift your foot. It should then travel to 100% throttle open and have a physical stop to avoid stretching the accelerator cable. Having taken your foot off the pedal it should return to where it was just below the height of the brake.

As you can see on the left I have used a small spring to aid the throttle butterfly spring in returning the pedal back up. Then an M4 bolt covered in nylon fuel pipe to act as a pedal stop. The right hand photo shows the pedal box to which the pedal stop in anchored. I used the bulkhead as the final stop for 100% open. Much better.